Technologies

Engineering and Tool Design

-

CAD Catia, Solid Works, Siemens NX and PTC Creo

-

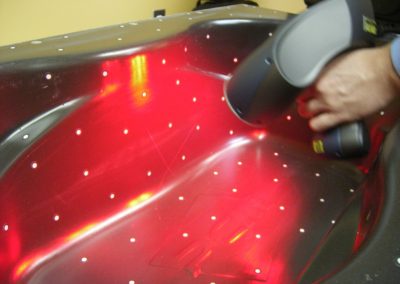

Reverse Engineering with laser scanner

-

Finite Element Analysis (FEA)

-

Concurrent Engineering by web conference

-

Secure file transfer via FTP site

Manufacturing

-

Clean room for prepreg & infusion

-

2 Composite departments

-

Modeling department

-

Welding & Assembly departments

-

Polishing & Finishing department

-

Overhead cranes in all areas with maximum capacity of 20 tons

Special Processes

-

Heat treatment: stress relief, tempering

-

Surface treatment: anodizing, chroming

Advanced Metrology

-

6 Laser Tracker (API – IFM/ADM/Faro)

-

Fixed or CMM integrated in 5 axis CNC

-

Photogrametry

-

CMM arm

Materials

-

Titanium

-

Electroformed Nickel (CORIMA technologies partnership)

-

INVAR Steel

-

Steel (P20, H13, Stainless, …)

-

Iron (Ductile & Grey)

-

Aluminum (7000 & 5000 series, M, …)

-

Carbon Prepreg

-

Carbon Fiber, Kevlar & Fiberglass

-

Resins : Epoxy, Vinylester, Polyester, …

-

Honeycomb panels (aluminum or composites)

-

Seamless modeling paste : epoxy or polyester

-

Foam : Polyurethane or Polystryrene

-

Tooling planks : epoxy or Polyurethane

-

Wood planks & MDF

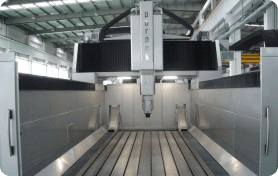

CNC Machining

-

3 CNC Five axis extra large and high speed machining (14’ x30’ x8’/4,3m x 9,1m x2,4m) (45’ / 13,7m capacity with 2 set up)

-

5 CNC center 3 axis (2 of 10 000 RPM / 126” x 43” x 30”) (3 of 15 000 RPM 60” x 30” x 20”)

-

Millturn 9 axes: 60’’ x 30’’ diameter | 1.5m x .76m diameter

-

CNC Milling: 13 feet: X: 160’’ Y: 60’’ Z: 60’’ |4m: X: 4m Y: 1.5m Z: 1.5m

-

CNC Milling Mazak 5 axes 10 feet: X: 118’’ Y: 36’’ Z: 36’’ |3m: X: 3m Y: 0.9m Z: 0.9m

-

CNC Milling Matsuura 5 axes: X : 36’’ Y: 36’’ Z: 36’’ | X : 0.9m Y: 0.9m Z: 0.9m

-

EDM: X: 22 ½’’ Y: 15 ¼’’ Z: 10 ’’ | X: 0.5m Y: 0.38m Z: 0.25m

- Vertical Lathe 40’’ | 1m diameter

-

Complete conventional milling and turning department