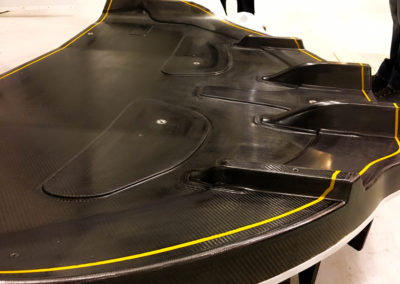

Molds for composites made of metal or composites

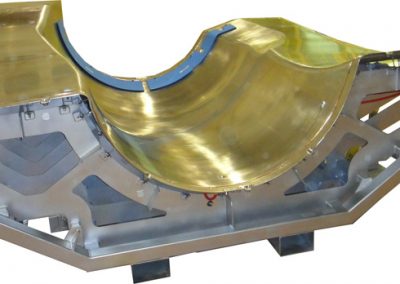

Machined metal molds for prepregs

- Machined metal –or-

- Electroformed nickel –or-

- Reinforced composite materials

- Thermal regulation system (heating or cooling)

- Injection and vacuum systems

Machined metal molds for prepregs

-

Invar

-

Steel

-

Aluminum

Composite material molds for high temperature processes

-

Machined metal

-

Electroformed nickel

-

Reinforced composite materials

-

Thermal regulation system (heating or cooling)

-

Injection and vacuum systems

Composite material molds for high temperature processes

-

Prepreg cured in autoclave

-

Out of autoclave prepreg

-

Infused epoxy and carbon fiber cured in oven

-

OPTION : Final machining of surface for higher precision (+- 25 microns / 0,001 in)

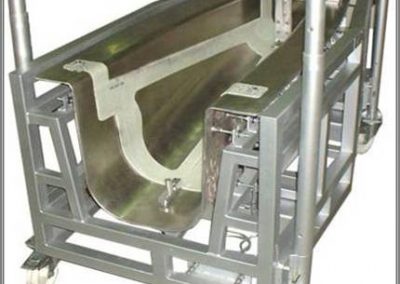

Molds with inflatable bladder for complex prepreg shapes

- Machined metal molds

- Inflatable bladder in high temperature sillicone

Molds for automated fiber or tape placement (AFP / ATP)

-

Deposition mandrels

-

Molds for autoclaving

Machined metal molds for prepregs

- Nickel skin (4 to 6 mm / 0,160 to 0,240 in)

- Steel structure with micro regulation system for the skin geometry

- OPTION : Thermal regulation system (heating or cooling)

- OPTION : Backing reinforcement in concrete/composite

Machined master models

- Epoxy tooling planks bonded and machined

- High temperature epoxy paste on honeycomb structure

- Seamless modeling paste on polyurethane or polystyrene foam

- Polyurethane tooling planks bonded and machined

- Wood or MDF planks bonded and machined

- Class A surfaces with finish up to 1200 grit

- Polyester, Vinylester, Epoxy and Polyurethane primers

- Scribe lines

- CMM inspection reports

We offer

- Finite elements analysis (FEA)

- Resin flow analysis

- Complete CMM inspection reports

- Final fitting and trial of molds

- Vacuum tests

- Trial parts

- TURNKEY development programs of prototypes, molds, secondary operations tooling and startup

- Durability warranties