AEROSPACE COMPOSITES MARKET: WE ARE LIGHTWEIGHT MATERIALS SPECIALISTS

Advanced Composite

The use of advanced composite materials has seen significant growth in aerospace and other sectors where lightweight components are now essential.

Composites are made up of reinforcing *fibers surrounded by a *thermoset or thermoplastic resin called matrix. Polymer Matrix Composites (PMCs) offer design advantages, lower density, high strength to weight ratio, excellent corrosion resistance as well as dielectric properties. Remarkable applications include the Boeing 787 Dreamliner, Lockheed Martin F22 Raptor, Northrop-Grumman B-2 Bomber, Bell-Boeing V-22 Tilt Rotor, and various fixed wing and rotary wing aircrafts. PMCs are also found in aerospace applications like rockets, satellites, and missiles. Other sectors, like transportation and marine industries, feature many other modern applications for PMCs.

Specialized Materials

Lucas Industries, and PCM Innovation Group, have a rich history of working with advanced specialized materials, initially focusing on nonmetallic patterns & molds for the aerospace composite industry. Over the past 20 years, Lucas has perfected precision tooling for the ever-growing composite industry. Lucas is now established as a go to supplier to shape a wide range of materials to high-quality precision tooling, specialized parts for both commercial and military aerospace applications.

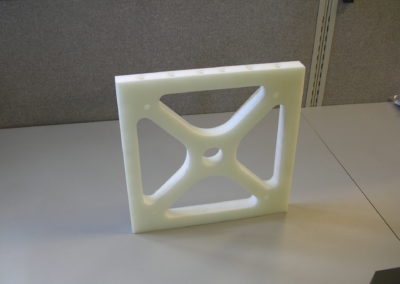

Foam Core

Lucas Industries has also developed abilities with lightweight foam core materials used in specific designs. By using composite plies on each side of a foam core layer, we create sandwich structures with exceptional lightness and stiffness, suitable for complex part geometries. Lucas uses different techniques such as thermoforming, cutting, milling, and drilling, to shape various foam chemistry compositions.

* Fibers include glass, carbon, and aramid.

** Thermoset resin matrices include epoxies, phenolics, cyanate esters (CEs), bismaleimides (BMIs), benzoxazines and polyimides).

*** Thermoplastic resin matrices include polyamide (PA), polyphenylene sulfide (PS), polyether imide (PPS) and polyetheretherketone (PEEK).

About Us :

Lucas Industries, a PCM Innovation company, excels as a leader and integrator supplying engineering and tooling solutions for the aerospace industry. Lucas and PCM solutions include assembly lines, manufacturing fixtures, molds for advanced composites, and prototypes or short-run production parts.

Serving customers primarily in aerospace, transportation, and energy sectors. PCM Innovation Group has six business units across Canada, the United States, and France. The group’s distinguished customers include Airbus, Boeing, Bombardier, Pratt & Whitney, Rolls Royce, and other prominent names in other industries.

Head Office

10 Precision Drive10 Precision Drive North Springfield, VT 05150

Phone

Certifications

ISO-9001

ITAR-USA

Military Controlled Goods Canada